Mechanics

High quality mechanic experience in large scale

As a trusted development partner, we are committed to continuously enhancing the entire product development process, from idea to final production. Our expertise lies in creating designs that seamlessly integrate the intelligence of electronic control systems with the functionalities of mechanical systems, providing innovative solutions tailored to your specific needs. Whether it involves interior or exterior components or the construction of critical mounting parts, we understand the importance of design, quality, function, and comfort.

-

Thermal management

-

Interior/exterior construction

-

Bodywork

-

Doors and flaps

-

CAD/CAM

-

Model creation

-

Light and sight

Our goal is not just to meet these demanding requirements but to exceed them. We go above and beyond to ensure that every aspect of the development journey is optimized for excellence. Our team is driven by a steadfast dedication to achieving the highest levels of performance, reliability, and customer satisfaction. By partnering with us, you can be confident that your project will benefit from our unwavering commitment to excellence and our relentless pursuit of innovation.

Customer Focused Mechanical Solutions

MEAtec, offers its customers the state of the art developments support from the design stage of the vehicle to the production of the complete vehicle with a dedicated team of machine designers and mechanical analysts with the strong fundamental knowledge needed to work effectively with customers. We support design of mechatronic systems for our customers' needs. Whether you need support to design a new product, develop an existing product design, or perform mechanical analysis, we have the flexibility to meet your unique requirements.

Our commitment to delivering cutting-edge solutions is further strengthened by our utilization of computer-assisted tools to simulate product performance, enhance product quality and durability, and reduce overall product development time and cost. This enables us to provide our customers with superior product designs and engineering solutions while maintaining our dedication to customer satisfaction and excellence.

Accelerating Efficiency Through Intelligent Modeling

The design process of a vehicle is inherently intricate and time-consuming, given the numerous components involved and their complex interrelationships. Traditional physical design methods can be costly and carry the risk of not fully meeting the desired design requirements of the vehicle. To address these challenges, mathematical designs offer a valuable approach by leveraging engineering and mathematical principles. By employing intelligent modeling techniques, we can achieve early validation of products and their features, resulting in shortened development times and reduced costs.

At MEAtec, we utilize industry-standard tools and technologies to provide a comprehensive range of services. These include Computer-Aided Design (CAD), Finite Element Analysis (FEA), Computational Fluid Dynamics (CFD). By leveraging these advanced tools and techniques, we ensure that our design process is efficient, accurate, and capable of meeting the demanding requirements of vehicle development.

Computer Aided Design and Manufacturing of Electric Vehicle

Computer Aided Design (CAD) is used to transform the basic product idea into detailed engineering design. It allows 2D technical design and 3D modeling. This technology get the designed values for all of the variables in the vehicle and runs them through the physics laws and vehicle dynamics equations implemented in the computer. In this way, weak points and areas that need improvement are found before the vehicle is physically built. Material wastage and time loss are avoided.

Computer Aided Manufacturing (CAM) is the use of software and computer-controlled machinery to automate a manufacturing process. Once your CAD model is imported into CAM, the software starts preparing the model for machining. Machining is the controlled process of transforming raw material into a defined shape through actions like cutting, drilling, or boring. The use of computer aided systems in product design and production provides more reliable products.

Finite Element Analysis (FEA)

Design analysis uses mathematical models where a certain behavior of the design in progress is captured and described by a mathematical apparatus. Complex models require the use of numerical methods like finite element analysis which is a numerical method used for analysis of structural and thermal problems during design process.

Finite element analysis involves breaking down the complex geometry of a mechanical component or system into an assembly of smaller (finite) and simpler elements. Each of these elements is modeled in a computer and subjected to mathematical calculations that test everything from the effects of electromagnetism on the component to physical stress analysis of mechanical components, such as gears, bearings, shafts, and others, etc. These calculations are described using partial differential equations that are systematically applied to each element to demonstrate how it would react to real world conditions.

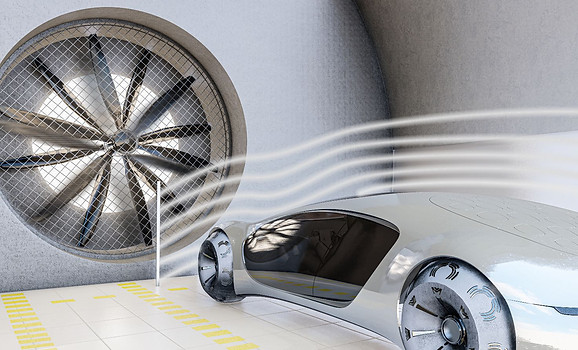

Computational Fluid Dynamics

Computational Fluid Dynamics (CFD) is a branch of fluid mechanics that uses numerical methods and algorithms to solve and analyze problems involving fluid flow. It uses mathematical models and computer simulations to predict fluid behavior and to study the effects of various physical factors, such as temperature, pressure, and flow rate. It is a multiphysics solution since it involves the interaction of multiple phenomena including fluid dynamics, thermodynamics, and conservation of momentum.

CFD in automotive industry has provided many advantages. This technology has delivered the ability to shorten cycles, optimize existing components and systems to improve in-car environment, and study the important external aerodynamics. Specifically it has shown measurable results through decreasing emissions with power train and engine analyses, increasing fuel economy durability, and performance through aerodynamic investigations.

Uniting Mechanics and Electronics for Automotive Excellence

The electric vehicle industry is constantly changing. More and more mechanical systems in vehicles are equipped with electronics according to the needs of customers. A large share of electric vehicle innovation involves combining formerly purely mechanical systems with the intelligence of electronic control systems to provide new ways of interacting with the vehicle. Such mechatronic systems require a concurrent design of mechanical, electronical and information processing sub-systems in order to reach the cost requirements of the electric vehicle industry.

Body Electronics are an electronic network of systems integrated into the vehicle that performs certain functions. Modern vehicles now contain a large number of subsystems that perform control functions, device diagnostics and safety functions. Components of vehicle body electronics include sensors and sensor interfaces, activators and monitoring circuits, as well as communication relays.

A few examples of features that can be obtained by adding body electronic to mechanical systems:

Acoustic Vehicle Alerting System (AVAS)

Vehicles can normally be recognized acoustically by other road users in traffic by the sound of their engines. However, electric powered vehicles run almost silently, especially at speeds below 20km/h. This makes them dangerous for pedestrians, blind people, cyclists and other road users. This danger has caused many countries to require electric vehicles to have an Acoustic Vehicle Alerting System (AVAS). The quality and technical qualifications that these devices must have are defined by ECE R138 in Europe, FMVSS 141 in America and GB/T - 2018 regulations in China.

The Acoustic Vehicle Alerting System (AVAS) simulates the engine noise of a combustion engine in the lower speed range to alert other road users to an approaching vehicle. Artificial vehicle sounds are generated using loudspeakers or actuators through the vibration of the vehicle’s structural elements proportional to vehicle parameters such as velocity, gas pedal position and gear.

Smart Glass Control

This system works with tiny liquid crystals that align with the application of electricity, making the glass appear transparent. In the absence of an electric current, these crystals randomly direct and scatter light, making the glass appear opaque.

Smart Glass can be made to darken or lighten based on the intensity of the sunlight for help to improve visibility for drivers. The system can also be used to control the amount of heat that enters the vehicle, which can help to avoid unnecessary use of the vehicle's air conditioning system and reduce CO2 emissions. Moreover, the windows that can be controlled manually or with a signal offer privacy to the user by switched from a clear to opaque appearance and eliminating the need for additional window treatments. This can provide a more pleasant and comfortable environment for passengers, as well as increase security and reduce the risk of theft or other crimes.

Power Door Control

Autonomous doors have the ability to operate without the need of an operator or door handles, allowing for a more convenient experience. By using your smart device, your vehicle can detect your presence and automatically open the appropriate door, making entering and exiting your vehicle a seamless process.

Intelligent door brake system and intelligent autonomous door support system are designed to support convenient opening and closing operations and prevent uncontrolled slamming. The obstacle detection system uses ultrasonic sensors mounted inside the vehicle's door handle to monitor the area around the vehicle for objects such as poles, traffic cones, curbs, other vehicles or even pedestrians. When the sensors detect an obstacle, it sends a signal to the smart door brake system. Intelligent door brake system stops the movement of the door or allows the door to move in the opposite direction. In this way, dents and paint scratches that may occur on the vehicle in the event of a possible collision are prevented.

Pedestrian Protection System

Pedestrians are the most endangered group in traffic. In most vehicle-pedestrian accidents, vehicles and pedestrians collide from the front. Pedestrian protection system is used for less damage to pedestrians in case of a possible accident.

The pedestrian acceleration sensor (PAS) provides information about the direction and level of impact by measuring in two channels that can record longitudinal and lateral vehicle accelerations during a collision. A pedestrian protection algorithm in the analysis software enables the type of collision to be rapidly identified. The signal propagation time also allows conclusions to be drawn about the location of the impact, for example the front right-hand corner or the middle of the vehicle. The control unit can then lift the hood in milliseconds, preventing the pedestrian's head from hitting the engine block. This allows for the pedestrian to impact against a more effective crumple zone, thereby minimizing the risk of injury.

.jpeg)